The Ultimate Unit Bearing, the last bearing you'll ever need. This Ultimate Unit Bearing uses 5/8"-18 studs on a 5 on 5-1/2" bolt circle, designed specifically for Spidertrax 35 splined axle shafts. It also has a left hand threaded spindle nut, intended for use on the left side of your vehicle (USA driver side).

But what makes Spidertrax axles outperform the competition in ALL areas of quality, strength, and price? Here is a list of key advantages on what makes our axle shafts stand out from the crowd:

We start with only the finest US grade 300M (used for the axle shafts) and aerospace grade E4340 (used for the yokes) billet chromoly. The E in 4340 stands for electric furnace (as opposed to a gas furnace which is more commonly used among our competitors) and yields superior results in heat treatment. We also carry out all CNC manufacturing operations right here, in-house, in Colorado USA. This allows us to provide an unmatched level of quality control while passing significant cost savings on to you.

Unlike other Dana 60 stub shafts, our approach to a two-piece stub shaft design adds an incredible level of strength, durability, and machinability. To start, our two-piece yoke incorporates a unique, ringed web design which connects and supports both ears securing the u-joint. This greatly minimizes deflection under load, providing a superior level of strength and durability to both the yoke and the u-joint. This ringed web also allows an axle shaft assembly to reach unheard of steering angles, achieving a maximum steering angle of 50 degrees! This design approach also creates machine friendly parts, allowing us to maximize the speed of our in-house CNC machines to pass significant cost savings on to you.

All heat treatment is done AFTER machining and never before. This provides far more strength than simply working with pre-heat treated material, rough cutting some splines, and calling it good. After heat treatment, we perform a deep freeze, or a Cryogenic freeze as it is commonly called, to the 300M material. We use a superior method for deep freezing that goes beyond simply cooling the part. After the axle shaft is heat treated, it is heated back up to a critical temperature at which point it is immediately deep freezed. This entire process improves the molecular structure of the axle shafts and has been a proven technique, when done correctly, in improving shaft strength and longevity. For those wondering why the 300M versions of these shafts are more expensive than the 4340 counterparts, this process, plus raw material cost, is the reason why.

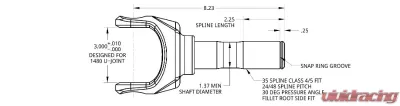

We turn down the stub shaft so the shaft diameter is smaller than the major diameter of the splines. This provides two key advantages. First, by choosing the correct shaft diameter we allow for an ideal amount of shaft torsion, critical for overall shaft longevity. Second, the axle shaft splines are protected from taking the full load on the shaft, in-turn making the splines much stronger. Anyone who has seen twisted splines on a shaft that has not been machined down like ours knows first hand what a difference this can make.

If you're building a complete Spider 9 with Ultimate 60 Knuckles, we know exactly what components you're running and how they are all designed to work together. Therefore, we can guarantee your Spidertrax 35 Spline Ultimate D60 Stub Shafts will fit and work perfect every time. We cover all critical areas of design, commonly missed by our competition, such as proper snap ring location, needle bearing tolerance and sealing, and the effective use of a thrust washer. All Spidertrax stub shafts come complete with snap ring, needle bearing, needle bearing seal, and thrust washer.

You're dealing with the actual company manufacturing your axle shafts, so you're not at the mercy of uncontrollable overseas nonsense and make-believe lead times.

Features:

- 3" U-Joint

- US grade 300M (used for the axle shafts) billet chromoly

- Aerospace grade E4340 (used for the yokes) billet chromoly

- Two-piece stub shaft design adds an incredible level of strength, durability, and machinability

- Spidertrax Ultimate Unit Bearings

⚠ WARNING:

Cancer and Reproductive Harm

https://www.P65Warnings.ca.gov

Spidertrax is a company that was founded in 1999 by Thomas Kingston and Eddie Casanueva. After graduating from college as a mechanical engineer, they moved their operation from New Jersey to Colorado, which is where the company stands even up to this day. The company produces various offroading parts used in the automotive industry.

Today, Spidertrax-equipped vehicles have dominated various offroading events, such as the King of Hammers.

Improvement Is Not Just For AestheticsSpidertrax is not your typical aftermarket company that only makes the products thicker and heavier. They focus on where a certain part typically fails and improves its design without compromising its weight. This is important, especially when racing. They use different techniques and calculate everything down to the smallest measurement to ensure that they would only produce the best.

Quality Products Inspired From RacingThe company actively participates in various racing disciplines by having a close relationship with different racing drivers. It allows them to gather feedback and real-life data that can help improve their products. Each component is designed to be stronger and lighter than stock, which is why they have become a favorite brand of many professional and amateur offroaders.

Purchase Spidertrax Products At Vivid RacingIf you are in the market for high-quality offroad parts for your vehicle, then Spidertrax is the brand for you. They have a wide range of products from drivetrain products, wheel spacers, mounts, and more. To learn more about Spidertrax and what they can offer, visit Vivid Racing and check out their list of parts that fit your specific need.

Spidertrax warrants only to the original purchaser that all products will be free from defects in materials and workmanship. The foregoing warranty is subject to the proper installation, operation, and maintenance of the product in accordance with the installation instructions supplied. Return Authorizations, or RAs, are required for all Limited Lifetime Warranty claims. Do not ship your product back prior to receiving an RA number from Spidertrax. RAs can be requested online under the My Account tab or by any method on the Contact Us page. Be sure to have your order number (confirmation number) ready when calling. Spidertrax reserves the right, before having any obligation under this Limited Lifetime Warranty, to inspect the damaged product and all costs of shipping the product to Spidertrax for inspection shall be borne solely by the purchaser. Spidertrax's sole obligation under the foregoing warranty is, at Spidertrax's option, to repair, replace or correct any such defect that was present at the time of delivery. The foregoing warranty is not transferable to another party and does not apply to any purchaser who bought the product from a reseller or distributor not authorized by Spidertrax.

Check out these other great products

.jpeg?q=90&p=thumb&w=200&h=200)

.jpeg?q=90&p=thumb&w=40&h=40) Brakes

Brakes  Driveline

Driveline  Electronics

Electronics  Handlebars & Controls

Handlebars & Controls  Package Deals

Package Deals  Wheel Accessories

Wheel Accessories  Wheels by Vehicle

Wheels by Vehicle  Tools and Maintenance

Tools and Maintenance  Universal & Repair

Universal & Repair  Vivid Racing Gear

Vivid Racing Gear